BRAND: AUDCO / YASH / L&T / MARCK / KSB / SPIRAX / KIRLOSKAR

We are specialist in BALL valves for Full bore / reduced bore in single / two / three pcs Design, ASME 150, 300, 600 in WCB / CI / SS body and other wetted parts & Flange rating 150#, 300#, 600#, 800#, 1500#, 2500#

These valves are named ball valve because ball is the main heart or important component of this valve. This ball helps us to open or close the supply line passing through this valve.

As we know the definition of valve is to make available the flow from one way to another way. It is completely one way supply system and that too can be controllable. In the system of ball valve the supply system is either allowed or stopped with the ball inside the body of this valve and that is why this is known as ball valve.

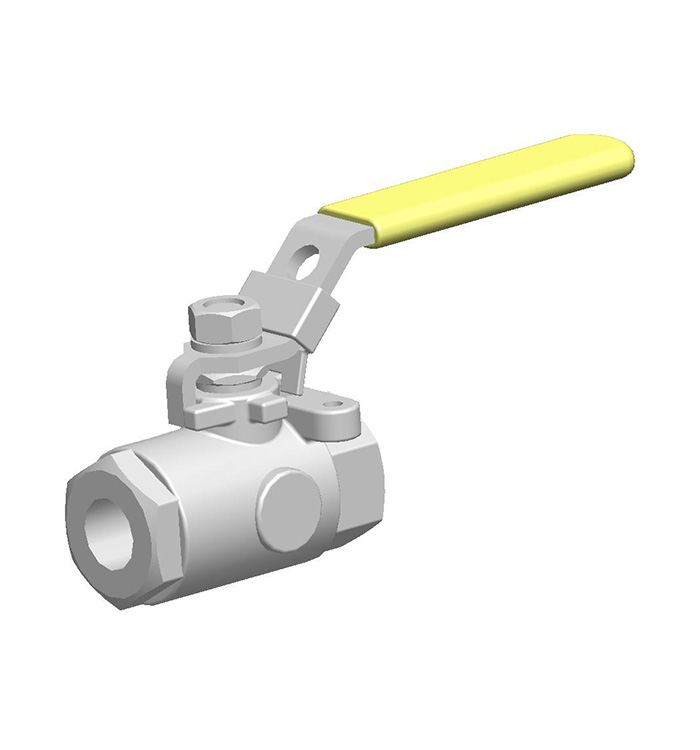

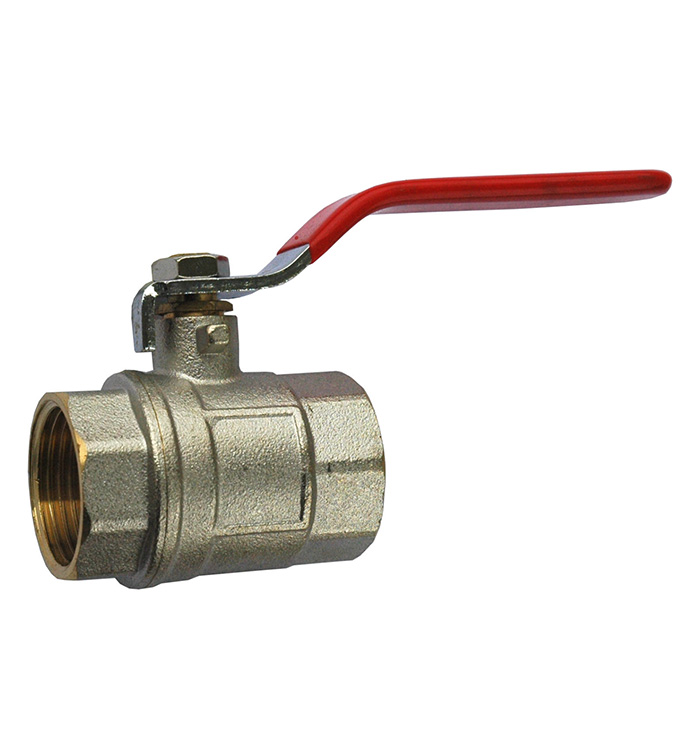

YASH” make Ball Valves are quarter-turn, straight through flow valves that have a round closure element with matching rounded seats that permit uniform sealing stress. Ball Valves are available in a variety of body styles, including one-piece, two-piece, three-piece and flanged body construction. They are used in situations where tight shut-off is required. The type of seat can vary with the valve pressure rating and materials of construction.

Ball valves are of soft seated, Floating Ball valve gives Zero Leakage, Tight Shut-off, and Easy smooth operation at temperature ranging from -200 to +1200 C. Metal to Metal seating offered for higher temperature services on request. The Stem Flange, on entire part of the stem, prevents the stem from blowing out pressure within the body cavity. This feature also allows replacement of stem packing while the valve is under pressure. These ball valves are used generally for quick shut off. Each of these ball valves forms offers specific advantages depending upon the requirements of the given application. Similarly they are designed using a wide variety of materials, as required by their application. Common Ball valve materials include brass, bronze, copper, cast iron, ductile iron, stainless and other steel types.

YASH” make Ball valves are manufactured as per BS 5351 and tested in accordance to ASME B16.34. Face to face dimensions to meet ANSI B16.10, and flange dimensions to meet ANSI B 16.5. Each and every Valve moving out of the works are passed through various vigorous quality checks right form raw- material stage to dispatch. An independent quality assurance team is responsible from procurement stage of raw - material and up to the performance warranty period

YASH offer Ball Valves in Fire Safe Design, Jacketed Design, Teflon Lined, Multiport Design, P.T.F.E. (PFA/FEP) Lined, Flush-Bottom Design, Extended bonnet Type Ball Valve

Technical Specifications:

- Size Range: 15NB – 600NB

- Range: ½” to 24”

- Pressure Rating : ANSI - 150#, 300#, 400#, 600#, 900#, 1500#, 2500#

- Standard: Generally conforming to BS 5351 and tested in accordance to ASME B16.34

- End Connections: Screwed Ends 800# to BSP / BSPT/ NPT (F) Socket Weld Ends to ANSI B 16.11 Inspection

- Body Type: 3 pcs/ 2 pcs/ 1 pcs, Flanged body

- Testing: Fire Safe Design, Jacketed Design, Teflon Lined, Multiport Design, P.T.F.E. (PFA/FEP) Lined,

- Application Industries: Manual, Gear Operated, Electro Pneumatic, Electric Actuated

- Wedge / Disc: Mounted

- Seat: PTFE/ Carbon or Glass Filled Teflon/ Graphite

- Ball : Floating, Full/Reduced Bore

- Material: SS 316/ SS 316 L/SS 304/ Cast Iron / Cast Steel / Forged Steel / PTFE

- Testing: Each valve is 100% tested to ensure leak-tightness at Shell, Seat and Gland

- Application Industries: Hydraulic oil, Water, Steam, Gas, Chemicals, Petrochemical, Power, Energy, Thermal, Refineries