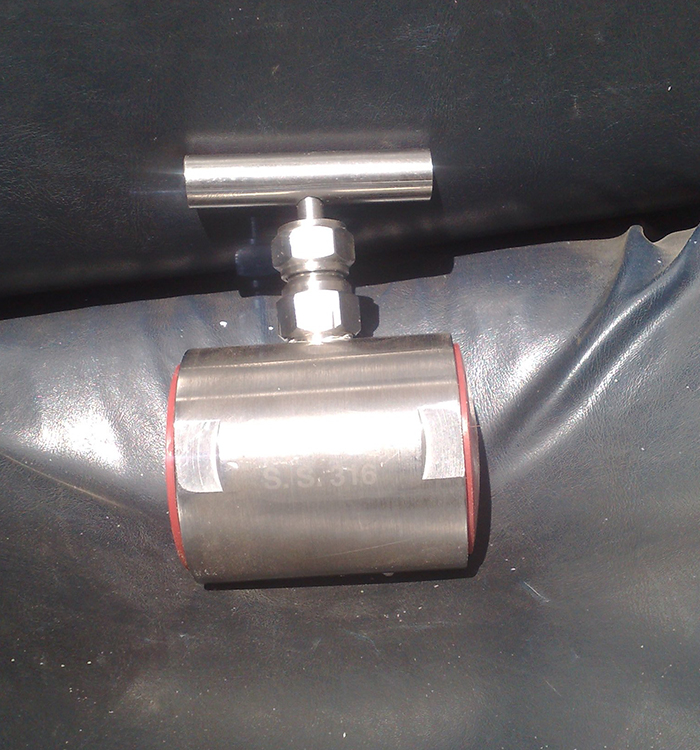

“YASH” make Needle valves come in bar stock as well as in forged construction various sizes, sealing styles, end connections and stem types. Main feature of Needle valves is that its stems are interchangeable with any of its valves of the similar configurations thus resulting in low cost and less inventory

We offer a range of needle valve that are fabricated from qualitative raw material and are as per the international standards.

They are designed in varied sizes ranging 1/8” To 2” (3 mm To 50 mm) and are designed as:

Straight and angle pattern

Precision machined stainless steel stem

Rugged and Compact Square forged body

Longer life with minimum maintenance

Low operation torque

Valves with double ferrule tube fittings

Technical Specifications:

- End Connections : Screwed NPT / BSP / BSPT, Male / Female, Tube ends, Combinations

- Body : One piece, socket weld ends , double bonnet, back seat, self centering tip

- Usage: For all kinds of high/medium/low pressure and vacuum applications.

- OD Size : 1/8'' to 2''

- Thread Size: ¼” to 2”

- Working Pressure: Suitable upto 10000 PSI

- Operation: Manual

- Maximum Temperature: - 65° to 450° F. (-54° to 232° C.)

- Gland Packaging: PTFE, Adjustable

- Vent: Optional

- Material: SS 316/ SS 316 L/SS 304/ CS or any special material

- Quality: Highest standard in Visual, Materials, Dimensional Accuracy, Operation, Leak-tightness, Finish and Workmanship

- Operation: Smooth, Easy, Low-Torque, Long life

- Testing: Each valve is 100% tested on Nitrogen medium to ensure leak-tightness at Shell, Seat and Gland

- Application Industries: Petrochemical, Power, Energy, Thermal, Refineries, Fertilizers