YASH” make Bleed valves are designed for use on products such as multi-valve manifolds, or gauge/root valves. Functionally, the valve vents line pressure either to atmosphere or to containment when used with optional barbed vent tube. Bleed valves are used whenever an instrument is removed from a system or to assist in the calibration of control devices.

Bleed Valves are also called Double Block & Bleed valve generally, as this valve is made up by two ball valve and one needle valve or two ball valve and a globe valve.

Double Block and Bleed valves have evolved to replace and add the process of bolting together individual valves to make the valves in one body. it saved a lot of space and material, it is the development tendency of the valve in the future. These new assembly of the double block & bleed valve provides great savings in weight, space and installation times especially in cage isolation. Double Block and Bleed valves have evolved to replace the process of bolting together individual valves to provide dual isolation. This new assembly provides great savings in weight, space and installation times especially in instrument & can be seen in the reduction of leak paths to atmosphere

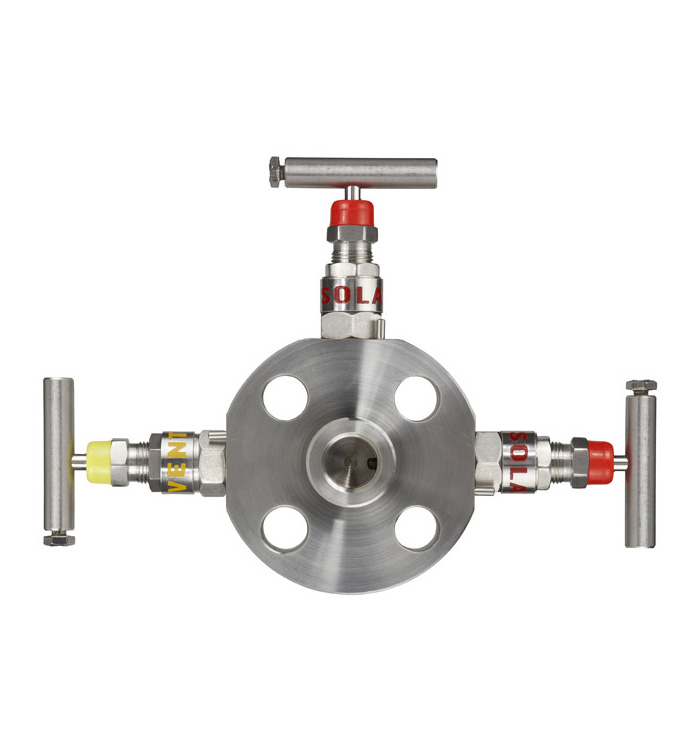

MONOFLANGES OR SINGLE BLOCK & BLEED VALVES

One Piece Ultra Slim line Forged Body combines a compact design with strength and reduced potential leak paths compared to conventional designs. Flanged Connections available on inlet or inlet and outlet in a choice of sizes and ratings to suit each particular application. Gauge Adaptors allow flexible positioning of gauges and instruments with a choice of designs available.

Technical Specifications:

- Size Range: 15mm to 600mm

- Pressure Rating :ANSI - 150#, 300#, 400#, 600#, 900#, 1500#, 2500#

- Standard: Designed and manufactured to conform API/BS/DIN STANDARD

- End Connections: Flanged connections to ANSI B 16.5

- Type : NYLON SEAT PACKING BLOCK VALVES BALL TYPE, BLEED VALVE NEEDLE TYPE, WITH BOLTED BONNET DESIGN

- Max Temperature: 52 degree C to +250 degree C depend on different material.

- Material: Stainless Steel, CS A105, Brass, Alloy steel

- Operation: Pneumatically controlled, electrically controlled - Smooth, Easy, Low-Torque, Long life

- Quality: Highest standard in Visual, Materials, Dimensional Accuracy, Operation, Leak-tightness

- Testing: Each valve is 100% tested to ensure leak-tightness at Shell, Seat and Gland

- Application Industries: Petrochemical, Power, Energy, Thermal, Refineries, Fertilizers, Chemical, Pharmaceutical